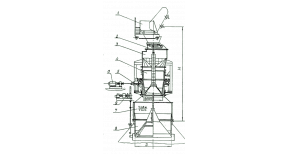

Bell charging appliance is designed for receiving the materials, charging them into the blast furnace and distribution on the furnace top section.

The bell charging appliances designed by Azovmash feature alongside with the standard design solutions (usage of the two gas seal gates, positive throughflow hopper, rotary charge distributor large and small bells) are provided with radial charge distributor in the form of a lifting ring around the large bell whose central part has an auxiliary opening.

Combination of the charge radial distributor with the auxiliary opening in the large bell ensures rational circular and radial distribution of charge materials on the furnace top that results in reduced coke consumption and increased blast-furnace capacity.

Dozens of blast furnaces of Ukraine are equipped with the charging appliances of Azovmash. They are also exported abroad.

Main units of the charging appliances:

- hauled receiving funnel;

- plate type valve;

- hopper;

- charge distributor;

- small bell with rod;

- drive;

- gas gate;

- filling apparatus;

- charge radial distributor.

| Furnace volume, m3 | V, m3 | H, m | D, m | Mass,ton |

| 1033 - 1386 | 30 | 10,08 | 4,2 | 197 |

| 1386 - 1709 | 40 | 10,525 | 4,8 | 214,8 |

| 2000 - 2300 | 45 | 12,36 | 5 | 229,5 |

| Gas pressure on the furnace top, MPa | 0,2 |

| Diameter of flow section of receiving funnel, m | 1,2 |

| Diameter of the valve bore size, m | 1,1 |

| Valve drive | Electro-mechanical |

| Installed charge distributor rotation speed, deg/sec (min-1) | 20,99(3,49) |

| Installed power of the distributor drive, kWt | 55 х 2 |

| Charge radial distributor drive | Electro-mechanical |

| Installed power of the radial distributor drive, kWt | 3 х 3 |

| Ring stroke, m | 0,9 |

| Ring travelling speed, m/sec | 0,03 |